Home > Company Introduction

Company Overview

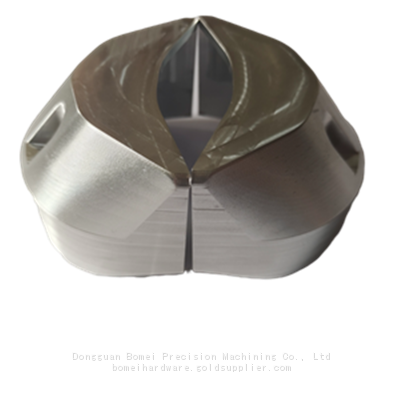

Bomei Precision Machining Co., Ltd is dedicated in providing custom-made CNC machining, milling and sheetmetal parts over 10 years. Our manufacturing possibilities range from CNC milling, turning, drilling and the production or assembly of molds and fixtures and much more. Our CNC-controlled milling and boring machines guarantee high-quality machining of both small and large dimensions.Our highly qualified employees realize the high demands of our customers with the latest CNC technology precisely and on time. Thanks to in-house modified machines with tailor-made bodies and optimized logistics, we can realize even the most difficult tasks in the shortest possible time. This means we are optimally positioned for contract manufacturing, above all.

-

ManufacturerBusiness Type

-

2012Year Established

-

5,000-10,000 square metersFactory Size

-

US$2.5 Million - US$5 MillionAnnual Export Value

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

51 - 100 People Total Employees

-

1-10 People Sales Staff

-

Fewer than 5 People Quality Inspectors

-

ISO9001 Product Certifications

-

US$2.5 Million - US$5 Million Annual Export Value

-

North America, South America, Eastern Europe, Oceania, Mid East, Western Europe, Central America, Northern Europe, Southern Europe, South Asia Main Markets

-

Shenzhen, Hongkong Port of Shipment

-

Machining Service Main Industry

-

Quality ControlWith over ten years of experience, we have built a database of standards and procedures committed to maximizing customer’s expectations for quality. Our planning of production realization process includes: 1. Understand the purpose of the customer’s products When the customer sends the PDF/CAD/3D drawings, we need to understand customer’s product specifications, requirements, application and assembly. For example, medical parts generally should have excellent quality, strict tolerances, shinny surface, and may need to withstand special conditions. 2. Analyze the customer’s drawings When we receive an order, our engineers will review the drawings, the process standards, and the production schedule, formulate detailed processing documentation, and use the most cost-effective solution to process the parts to ensure that the accuracy are met. 3. Manage From Raw Material coming in to products shipment All products have to go through. 4 checks in the whole process: Raw material inspection, In processing inspection, Final inspection, Outgoing inspection.

Quality ControlWith over ten years of experience, we have built a database of standards and procedures committed to maximizing customer’s expectations for quality. Our planning of production realization process includes: 1. Understand the purpose of the customer’s products When the customer sends the PDF/CAD/3D drawings, we need to understand customer’s product specifications, requirements, application and assembly. For example, medical parts generally should have excellent quality, strict tolerances, shinny surface, and may need to withstand special conditions. 2. Analyze the customer’s drawings When we receive an order, our engineers will review the drawings, the process standards, and the production schedule, formulate detailed processing documentation, and use the most cost-effective solution to process the parts to ensure that the accuracy are met. 3. Manage From Raw Material coming in to products shipment All products have to go through. 4 checks in the whole process: Raw material inspection, In processing inspection, Final inspection, Outgoing inspection. -

Our ServicesOur mainly products include CNC Precision Machining Parts, CNC Turning Parts, CNC Milling Parts, and Sheet Metal Parts, everything from simple processes to advanced precision. Bomei provide customers with solutions from raw materials to process engineering and manufacturing. This reduces the cost of communication and assembly costs for customers. When Bomei is your custom made parts partner, you can expect: > Fast delivery date (5-30days) > High-precision(Tolerance +/-0.01mm) > Free samples(For customers’ approval) > Saving money(Low-volume manufacturing services) > After-sale(Dedicated experience team and problems solved)

Our ServicesOur mainly products include CNC Precision Machining Parts, CNC Turning Parts, CNC Milling Parts, and Sheet Metal Parts, everything from simple processes to advanced precision. Bomei provide customers with solutions from raw materials to process engineering and manufacturing. This reduces the cost of communication and assembly costs for customers. When Bomei is your custom made parts partner, you can expect: > Fast delivery date (5-30days) > High-precision(Tolerance +/-0.01mm) > Free samples(For customers’ approval) > Saving money(Low-volume manufacturing services) > After-sale(Dedicated experience team and problems solved) -

Our TeamThe core members of the team have entered this industry since 2007 and become industry leaders, mainly engaged in the non-standard automated machinery and equipment industry. Our sales support & manufacturing teams ensure that every of our customer receives a comprehensive solutions for any need they have. >Fast Efficient Communication >Every On-time Delivery >Flexible Payment Terms >Saving more money through our professional production process

Our TeamThe core members of the team have entered this industry since 2007 and become industry leaders, mainly engaged in the non-standard automated machinery and equipment industry. Our sales support & manufacturing teams ensure that every of our customer receives a comprehensive solutions for any need they have. >Fast Efficient Communication >Every On-time Delivery >Flexible Payment Terms >Saving more money through our professional production process